Urgence gaz 0 800 028 800

For Teréga, managing the environmental impact of its activities is a priority

To be an exemplary gas actor, we apply our environmental commitment at all levels of our organisation. When it comes to managing the environmental impacts of our activities, we systematically implement the AVOID-REDUCE-COMPENSATE (ARC) methodology. That approach is rooted in our internal global BE POSITIF project.

How does Teréga write impact management into its priorities?

Our understanding of managing the impacts of our activities is based on consideration of environmental challenges at each stage, starting with the preliminary phases of a project, but also in the operation of our installations. This means that, from the pre-construction phase, and then on to the operation of our installations, we include environmental considerations, with strict application of:

regulations;

norms;

standards;

internal procedures.

We are constantly searching for new virtuous solutions.

Waste management and recovery: Teréga is on the front line

Before setting up a good waste management and recycling system, the first thing the Group seeks to do is limit waste as much as possible. Take the example of coffee machines: a “zero disposable cup” project was introduced in the head offices in 2020.

Looking at the waste produced within the Group: selective sorting is in place, to guarantee good management along the sorting chain, and Teréga is working to find the best approved processing routes.

The aim is to encourage repurposing and recycling. Good waste management also requires the staff and contracting companies to get on board. To that end, staff are made aware of selective sorting and environmentally friendly ways of reducing the waste they produce.

Lastly, internal organisation that reaches out to the different sites is in place to ensure the day-to-day management of waste, facilitating internal processes used by employees and colleagues to deal with waste.

Teréga combats noise pollution

As part of our wish to set an example, we have introduced actions to reduce the noise level of our installations. To do that, we have called in professionals working in the field of acoustics to develop and introduce solutions which have proved their worth. For example, we have installed silencers in the flues of the compression stations at Sauveterre and Lussagnet.

Knowledge of the soil: an absolute environmental priority for Teréga

To operate efficient management of polluted soils, you have to know the state of your soil. Since 2009 we have been conducting a systematic campaign to analyse soils, even though there is no such obligation in the regulations. It has enabled us to identify polluted zones and to instigate clean-up operations. Innovative treatment solutions have been adopted, such as the re-use of materials from excavated soil in cement works.

As part of our ISO 14001 certified environmental management system, we are also taking action to control and manage the quality of water and soils. Detailed instructions are therefore sent out to contracting companies and operators. Our aim is to manage any spillage risks through various measures such as:

storage of chemicals on spill trays;

anti-pollution kits on sites and on heavy plant;

raising awareness among internal staff and teams working on construction sites;

carrying out anti-pollution kit deployment exercises;

the reporting of any chemical spillage or any discovery of previous pollution and the introduction of suitable treatment.

Industrial waste monitoring

Teréga, has introduced an environmental self-monitoring programme to its Classified Installations for the Protection of the Environment (ICPEs).

That self-monitoring, which is one of the essential links in managing discharges and preventing pollution, has two main objectives, namely:

ensuring proper control of processes and identifying discrepancies, if applicable, so that they can be corrected as quickly as possible,

ensuring the characteristics of emissions are in accordance with the maximum values set by regulations.

To do that, Teréga relies on the expertise of approved laboratories to carry out periodic checks on the following effluents:

atmospheric emissions from combustion facilities (monitored parameters include: NOx, SOx, dusts etc.),

process water following treatment and prior to discharge into the natural environment at the Lussagnet storage centre.

These results are then sent to the Administration (DREAL).

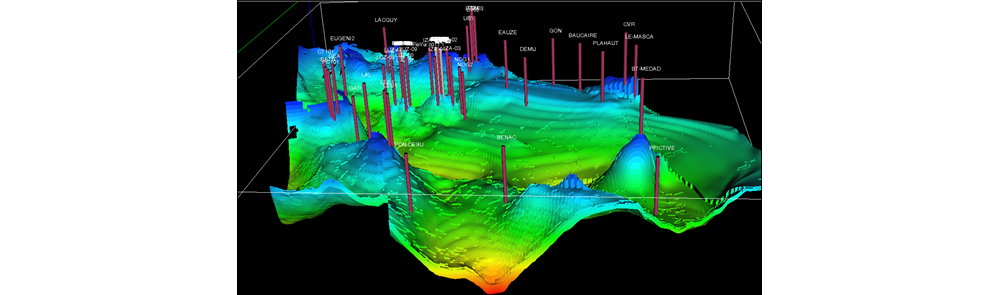

Gas storage: monitoring of the aquifer at Teréga

Our gas storage facilities at Lussagnet and Izaute are located about 500 metres underground, in a geological aquifer (water-impregnated porous rock) known as a “reservoir”. We therefore continuously monitor the effects of our gas storage activities on the aquifer, drawing particularly on the skills of our Geoscience department.

Our procedure stipulates in particular that we should monitor:

the pressure in the reservoir (in the area occupied by the gas) and the overlying strata:

the pressure in the aquifer (around the area where the gas is present);

the water and gas quality.

To understand all these issues, we carry out:

surveillance work;

research work on the regional hydrogeology with the BRGM and the Adour-Garonne water agency (GAIA) project;

research work on the chemical and biological impact of the gas on the aquifer, with the University of Pau and the Pays de l’Adour (UPPA) in particular.

Reporting linked to aquifer monitoring: what is that?

Every month we send the DREAL our logs showing the pressure and stock of gas, along with monitoring data on the level of the aquifer (at the boundaries of our storage) and in the storage overburden.

In addition, once a year, we also send:

a summary of work carried out (surface and subsurface);

a report on draw-off and injection campaigns;

a report on pressure monitoring (overburden and aquifer/reservoir).

In addition, a water quality and aquifer chemical status report is prepared for 17 control points, located around the boundaries of our storage. The aim is to check the quality of the water and to show the absence of any transfer of chemical elements present in the gas.