Urgence gaz 0 800 028 800

Teréga puts energy optimisation at the heart of its objectives

Initially included in our environmental approach, we have now turned energy management into a target in its own right. Our activities therefore aim at achieving energy efficiency, helping modernise our industrial facilities and managing them in such a way as to optimise consumption, developing self-sufficiency solutions, favouring a sustainable construction approach, etc.

Teréga combines energy management into its corporate culture

As an energy transporter and responsible actor, we are committed to setting an example in the field of energy management. The demonstration of our dedication to good resource management is founded in particular upon a specific management system. It has been put together in accordance with the ISO 50001 standard and has been certified since 2014.

The ISO 50001 action plan breaks down into different processes aimed at optimising energy consumption. They cover:

the management of facilities, particularly through the deployment and enhancement of the Optimus tool which covers the use of our transport and storage compressor resources;

diffuse losses, with the commissioning of the three latest models of electric compressors. Their seal-free technology means we no longer have the associated leaks. We are also developing a R&I project on the recovery of leaked material from compressor seals and its reinjection into the grid;

venting, with the acquisition of our own recompression module for maintenance work (Mobile Comp). We also have recompression projects in the compressor venting gas grid (RECOMP) at Lussagnet (storage and compression station), Barbaira and Sauveterre;

buildings, with an Energy Performance Contract (CPE) signed with our service provider Vinci, for reductions in consumption by 2022.

BE POSITIF

Included in the company’s BE POSITIF programme, energy optimisation is a process that extends to all departments, every single worker, and all our activities (transport and storage). This approach further supports the evolution in our corporate culture to put Teréga at the heart of energy transition.

Teréga supplies itself with renewable electricity

While our actions to limit greenhouse gas emissions make a big contribution to energy management within our activities, our improvement targets go much further than that. So, since 2017, we have been supplying ourselves with renewable electricity across 16 of our industrial and tertiary sites (those above 36 kVa). They include the Lussagnet storage facility, which alone accounts for 85% of consumption on those sites.

Taking this to the next level, one of the BE POSITIF programme targets is to become self-sufficient in at least part of the energy needed to run our facilities, from renewable sources. A project is under way to develop a solar farm at Lussagnet, in partnership with regional technical specialists and in coordination with departments at the CRE. Named SOLUS, it is planned to produce solar energy of around 10 MWp (MegaWatt peak). It is due to go live during 2023. The solar farm will supply our storage sites with around 20% of their electricity needs.

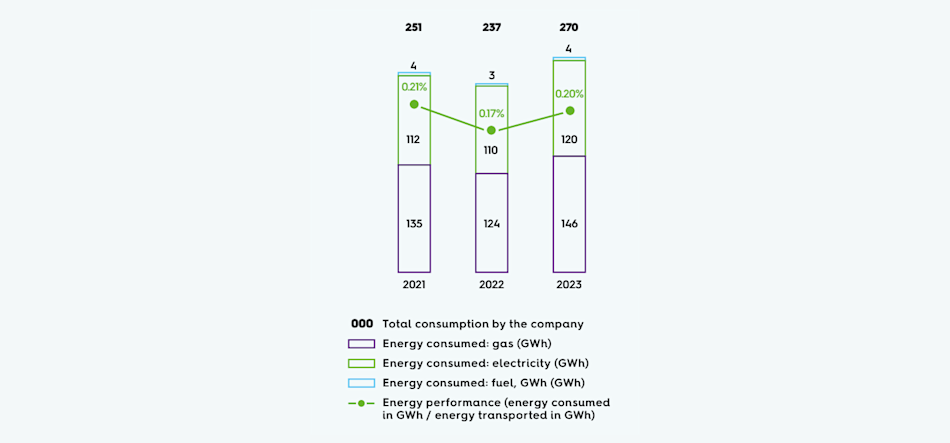

2021-2023: proven energy performance

Sustainable construction: another area for energy optimisation at Teréga

Our desire to improve and set an example can be seen in practical ways through the consideration of energy criteria when designing and purchasing equipment. Starting with the study phase when modifying or developing our infrastructures, we seek out the best available techniques in terms of energy efficiency. The desire here is to modernise our industrial facilities and to enable them to perform the same tasks but at the same time to optimise their energy consumption.

This means that, when constructing new buildings, a cutting-edge, green and sustainable approach has been adopted, based on five requirements:

worksites that respect the environment and our neighbours;

successful integration into the countryside;

greater comfort and lower energy consumption;

use of renewable energy, particularly from photovoltaic panels;

the choice of high-quality materials.

In addition, since 2008 a number of our completed projects have received the NF High Environmental Quality (HQE) mark for tertiary buildings. That certification shows that operations have been planned, designed and completed in accordance with the requirements of the reference standard.

How does Teréga apply its HQE system?

The HQE system involves meeting fourteen targets aimed at creating a healthy and comfortable internal environment, limits on the building’s impact on the environment (waste, carbon emissions etc.) and the reduction of energy and water requirements.

It also requires that three of the fourteen targets should receive a “high performance” rating, meeting the highest criteria in that area. As part of the work, we have prioritised the following targets in particular:

a low-impact building site, with optimisation of waste management, limiting consumption of resources and eliminating pollution;

exemplary energy management, with the optimisation of insulation or the installation of so-called “renewable” energy sources;

business waste management, with a systemic approach to operations being introduced across all Teréga sites.

How is Teréga making digital one of its energy management targets?

The BE POSITIF programme extends across the whole business and every one of our activities. As such, it is also being rolled out through our digital strategy. To that end, we are committed to a digital frugality approach: in other words, how to do more with less? Because digital represents 4% of the world’s greenhouse gas emissions, working out at more than the emissions generated by civil air traffic!

Thus, at an internal digital convention, we presented a report on our digital carbon footprint, accompanied by proposals for improvements on two aspects: equipment (smartphones, computers etc.) and printouts. An action plan was put in place, accompanied by tracking indicators accessible to everyone. We have also extended the plan to computing and data storage centres, networks and applications.

As part of our digital frugality action plan, we have defined a number of areas for intervention:

to anticipate power and performance levels;

to reduce the number of pieces of equipment in use;

to work on device service lives, by testing environmentally responsible items;

to extend the service life of equipment in use;

to study sharing the use of equipment;

to encourage mixed use (professional and personal) of a single piece of equipment;

to raise awareness of essential tasks (size of emails, Internet research etc.);

to facilitate access to video meetings to avoid physical travel by car;

to encourage a cloud-based approach for our practices, to optimise maintenance and energy consumption;

to develop the use of low-code among our developers;

to encourage two-sided printing in black and white;

to use computing centres supplied with green energy.

Focus areas for encouraging digital frugality