Urgence gaz 0 800 028 800

What is methanisation?

Methanisation is a process whereby renewable gas is produced from organic waste. It is a virtuous repurposing of waste that encourages the operation of a circular economy and makes a contribution to the ecological and energy transition.

How does methanisation work?

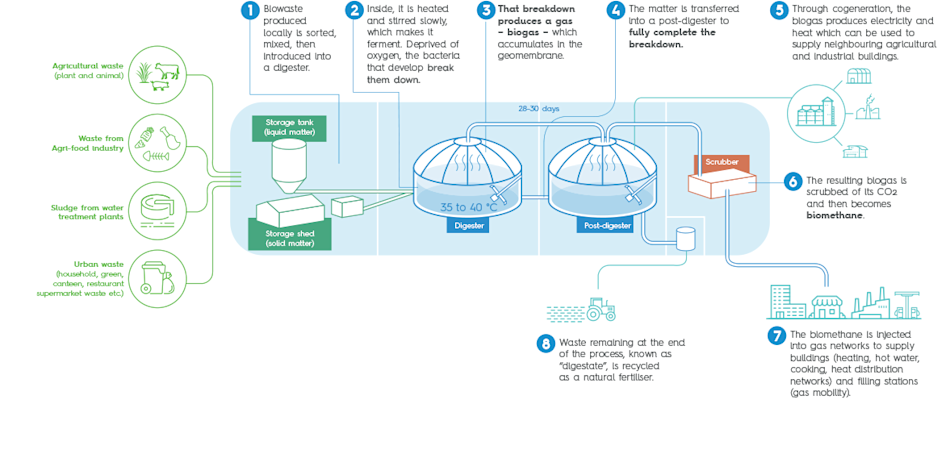

Methanisation (or biomethanisation) is a process based on the natural fermentation of organic matter to produce biogas. The raw materials used (or “inputs”) are organic waste from farming (manure, slurry, crop residues etc.), from agribusiness, or from local authorities (sewage sludge, household biowaste, cuttings from roadside verges etc.).

This process takes place within a methanisation unit. In the large tank, called a “digester”, the organic waste becomes part of an anaerobic digestion process: it is heated and broken down by bacteria and micro-organisms in the absence of oxygen. This natural activity produces methane.

The biogas obtained from methanisation can be used directly to produce heat and electricity. It can also be injected into the natural gas grid to encourage the consumption of renewable gas at a regional and national level. In this case, the biogas needs to be purified so that its characteristics are similar to those of natural gas. This is where we talk of “biomethane”.

Stages of the methanisation process

The advantages of methanisation

The production of biogas and biomethane fits into the circular economy model and has positive knock-on effects: local energy production that cannot be moved elsewhere, job creation, an answer to the problem of how to manage agricultural co-products, the replacement of synthetic fertilisers etc. Here are the three direct advantages of methanisation:

Repurposing of waste

Methanisation provides a use for organic waste, producing renewable energy and organic fertiliser. It allows the processing of oily or very wet non-compostable organic waste.

It is also a way of achieving a reduction in the quantity of organic waste requiring treatment in other sectors.

Reduction in greenhouse gases

According to “Methanisation in 10 questions” from Ademe, every kWh of biomethane injected into the gas grid could avoid 200 g of CO2 equivalent. There are two reasons for this positive impact:

Methanisation allows the methane produced naturally by the breakdown of organic matter – particularly livestock effluents – to be captured and utilised.

Biogas and biomethane can replace fossil fuels such as oil, coal and natural gas, because they can be transformed into heat, electricity or renewable fuel (BioNGV).

Digestate: a natural fertiliser

Digestate is the portion of the waste that remains at the end of the methanisation process. It can be exploited as natural fertiliser, as a substitute for chemical fertilisers.

To optimise its use, a digestate phase separator can be used. In fact, the liquid and solid phases do not have the same properties: the one is a fertiliser, the other is a soil improver.

Dry or wet methanisation?

There are different plants for dry and wet methanisation, depending on the nature of the inputs. Indeed, dry systems can, for example, accept a larger proportion of dry matter, whereas wet systems allow better mixing of the matter. The choice of technology will therefore be governed by the organic waste being put in.

Offering high-performing technologies that are simple to use is a major issue when encouraging the development of biomethane. That is why Teréga, through its subsidiary Teréga Solutions, is involved in the development of innovative methanisation techniques through partnerships with:

Chadasaygas which is proposing a discontinuous dry methanisation technique, particularly suited to agricultural methanisation when the inputs are largely solid animal waste.

DualMetha which has been recognised for its unique eponymous methanisation process, combining discontinuous dry methanisation with continuous wet methanisation.

How does Teréga support methanisation projects?

Since 2010, we have actively been supporting the development of the industry, drawing on our expertise as a gas infrastructure operator. We support farmers and other methanisation project owners in setting up production units in our region and injecting biomethane into our network.